They approached STRIDE with their idea and STRIDE immediately saw the potential for the product to be put through it’s paces through the project’s New Product Development Programme. The aim was to build a structured route from idea into a fully formed product that covered ideation, design, prototyping, product testing, commercialisation and impact. The STRIDE also brought their Team X initiative, allowing Protoedge Solutions Ltd to access skills it currently didn’t have.

Ideation

The initial stages of the project were spent turning their initial concept, originally called Fire In The Hole, into something more strategic and commercially sound. Under consultation from STRIDE, the product’s name shifted to Hold Fire, part of a broader effort to make the idea more marketable.

Excerpt from branding session by STRIDE

From the start, the potential for Intellectual Property rights were taken seriously. STRIDE consulted with their IP expert from the University of Plymouth who ran patent searches and guided Protoedge Solutions Ltd through a patent application in the early stages of their time with STRIDE. Alongside this, STRIDE mapped out business models, explored licensing opportunities and considered legislation and accreditation requirements, including ISO standards. Insurance bodies and other critical influencers were also identified at this stage.

The Team X initiative, that uses in-house skills of the STRIDE team to aid a product’s development, proved invaluable. STRIDE was able to gather IP Specialists, product designers, marketers and people who understood a product’s route to market as part of the standard service, saving Protoedge Solutions Ltd time and money. STRIDE was also able to give Protoedge Solutions Ltd marketing consultancy with our friends at Wayfinder Solutions Ltd who helped with the first investor pitch decks and the early gate reviews to see if the product was ready to move forward.

Product Development

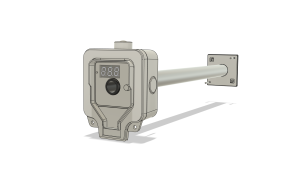

The first major breakthrough came with the physical design. Rather than design and build everything from scratch, STRIDE suggested a more pragmatic approach: to use a weatherproof socket already on the market for Hold Fire’s housing. This meant that energy could be focused on the internal components, rather than tooling for an entirely bespoke shell.

STRIDE aimed to keep the design restraints realistic from the outset in order to maximise the time Protoedge Solutions Ltd had with the team, as well as balancing budget and scale. The idea was to blend standardised parts with custom elements that would keep manufacturing costs down. STRIDE led on this design, working out what had to be taken off-the-shelf and what needed to be more bespoke.

Collaboration between STRIDE and an electronics expert helped develop the internal circuitry, and was designed with future-proofing the product in mind. This allowed the internal circuitry to have the room it needed for future development, including WiFi modules, or extra lighting.

CAD design by STRIDE

In house CAD design and 3D printing of prototypes allowed for rapid prototyping, allowing STRIDE to work through multiple design tweaks without the need for external suppliers, further saving Protoedge Solutions Ltd time and money.

A grant of £2000 was also awarded to the project, which supported the electronic development of Hold Fire and STRIDE helped write technical specifications and gather costings. Technical drawings also formed part of the patent application.

Prototyping

A large part of the prototyping was done by STRIDE in-house using a 3d printer. This was to enable costs to be kept to a minimum whilst allowing flexibility to refine the product as needed before committing to a ‘final’ design.

A bill of materials was drawn up, alongside early manufacturing cost models. Several assembly partners were identified for potential scale-up. Suppliers were considered, including options through the University networks and lower-cost suppliers from overseas.

Market testing plans were also put in place. STRIDE began discussions about giving live demonstrations to the Fire Service to prove the product’s value in a ‘real’ setting.

Testing

Testing the product wasn’t just about making sure the product worked, it was also about proving whether Hold Fire had market potential. Our consultants designed targeted questionnaires for industry reps and users within the Fire Service that asked everything from the pricing to the perceived functionality.

As the design of the product had settled by this point, the focus became about installation, software and integration of the product. Gathering this data and feedback would help sharpen commercial opportunities. Live demonstrations and video of the product being used were also earmarked as strong opportunities for marketing.

Commercialisation

STRIDE understood that the commercialisation of Hold Fire should happen alongside development, rather than being done in the final stages of the project. Team X and Wayfinder consultancy helped shaped the brand identity. The name change, from Fire In The Hole to Hold Fire, was suggested by STRIDE and resonated strongly with the client and from this point Hold Fire was able to start creating brand materials, logos and a website for the client.

With that in place, the client attended a national fire industry event which was the first public test of the product. This generated genuine interest from the industry and opened doors. A clear commercial strategy started to take shape, that covered business-to-business and business-to-customer routes to market. Feedback from both potential customers and the Fire Service itself helped develop Hold Fire’s positioning and helped build trust in the product.

Next Steps

With STRIDE’s help, Protoedge Solutions Ltd was able to cover a lot of ground but there are still considerations for the product:

- Finalise and field-test the prototype with the fire service, including live demos

- Capture footage and data for marketing and future sales

- Prepare licensing pitch decks for potential partners

- Finalise the business model — balancing early in-house production with scaling

- Confirm costings for full-scale manufacture

- Launch preparations and early market engagement

Success and Impact

For STRIDE the biggest success of the project has been the collaborative structure behind it. By having Intellectual Property, design, marketing and commercialisation expertise under one roof the project was able to move faster, cost less, and help drive confidence in the product

What started as an early stage concept is now a market ready product with a patent, a clear brand identity, a manufacturing pathway and a route to market. This has been a project that has proven how a structured product development programme can take a great idea, give it the direction it needs and turn it into something not only tangible, but something that can, in Hold Fire’s case, save lives.